Most lasers are made from solid materials, but some of the earliest lasers are not. Liquid dye lasers have been used for decades because running a liquid through the optical cavity avoids “optical exhaustion” in one’s gain material. And I’ve seen some plastic lasers before. I’ve just never run across one that was stretchy. Until now.

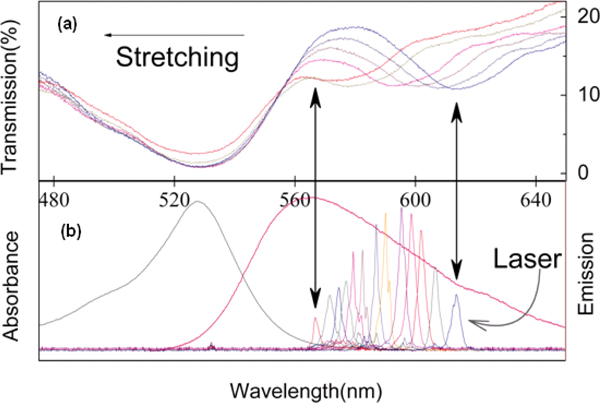

In the new open access journal, Optical Materials Express, there’s a paper about a visible laser made of a polymer, whose output color changes as you stretch it.

As the paper’s authors at Youngstown State University and Case Western Reserve University explain in the paper, tunable stretchy lasers aren’t new: they were reported as early as 1980. What is new is that Guilin Mao and the other paper authors developed a way to mass-produce stretchy lasers using extrusion, which is used for many plastics.

They made large sheets of layered material, including a gain layer made of elastomer doped with a dye long used in liquid dye lasers (Rhodamine-6G) that was sandwiched by two 128-layer stacks of alternating layers with different refractive indices. The stacks create distributed Bragg reflectors — in other words, they act as mirrors to reflect light back into the gain layer.

The laser was pumped with green light from a frequency-doubled Nd:YAG (a solid glassy material) laser. When it wasn’t stretched, the extruded laser shone red. When it was stretched the color changed to shorter wavelengths until, at almost a 20% stretch, it shone green.

That methods used to make the lasers are all high-throughput roll-to-roll production methods. So one could make huge batches of these lasers pretty cheaply. The expensive part would probably be the pump laser. Very very cool!

Read the paper: Co-extruded mechanically tunable multilayer elastomer laser.